Description

Biomass boiler PelleTech Agro 200

- O Biomass boiler PelleTech Agro 200 offers a complete Hot Air Generation System, ideal for heating Poultry farms and glasshouses . Suitable for any Professional & Industrial Application .

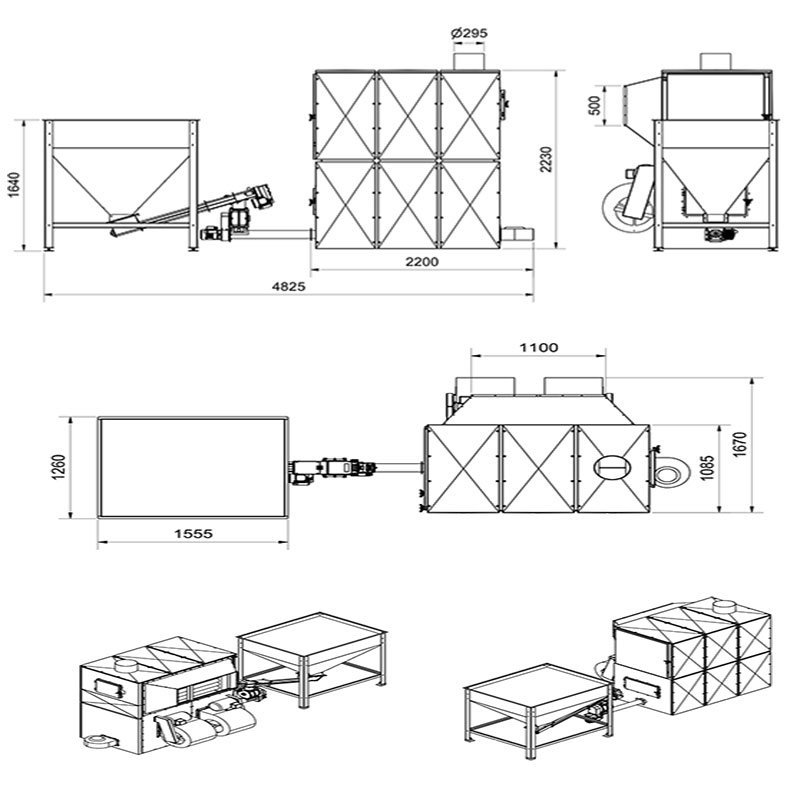

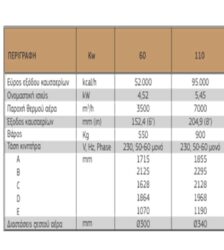

- Available versions 200 Kw & 350 Kw

- Combustibility : Olive kernel, kooky, pellet, Maximum moisture content of Biomass Fuel up to 30% .

- Biomass boiler PelleTech Agro 200 of Greek manufacture , produced in accordance with the Machinery Directive and has CE marking

Advantages :

- Innovative 7-stage reciprocating grate burner system that allows the combustion of biomass even with increased humidity up to 30% .

- Very high efficiency and maximum economy thanks to controlled combustion conditions and minimal losses.

- Full combustion control thanks to the selection of the appropriate parameters for each fuel type.

- Independent dual air supply of primary & secondary combustion for excellent combustion and proper utilization of biomass fuel, without losses.

- Combustion chamber made of stainless steel coated with cast iron , heavy duty for longer life.

- Easy installation and cleaning with very low maintenance costs.

- Stable operation and performance for smooth heating of the space.

Description :

- Burner made of AISI 304 stainless steel.

- Protection from flame return.

- Electronic heat regulator for automatic management .

- System Automatic cleaning

Technology :

1. Air grids, to supply the warm air inside the room

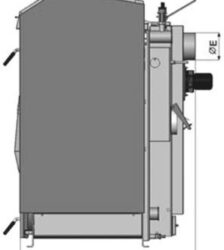

2. Heat exchanger and flame burners, where the hot exhaust gases transfer all the heat to the fluid (clean hot air)

3. Bimetallic combustion chamber made of AISI 304 stainless steel lined with cast iron plates at the contact points of the flame with the walls, which ensures very high resistance to the chemical processes and temperatures that develop in the combustion chamber.

4. Burner with stainless steel body and grate consisting of cast iron insert.

5. Exchanger cleaning and inspection doors: Exchanger cleaning doors that also function as safety and overheating protection doors (lined with vermiculite refractory material).

6. Exhaust duct to the chimney.

7. Reinforced fuel feed screw: prolongs the average life of the fuel feed system.

8. Electromixer : Driven by an electric motor and allowing the screw to carry the fuel

9. New generation dual fuel engines: High efficiency with very low energy consumption, meeting all new European directives.

10. Fuel storage silo: With a large capacity of 1 m³

11. Exhaust gas evacuation to the chimney

12. Flue gas temperature control system: electronic flue gas temperature sensor that provides feedback to the boiler control system and results in the adaptation of the combustion to the prevailing conditions and the exhaust gas output at very low values of 180 °C.

13. Cast iron power supply system: With rotating compartments (SBP) for supplying combustion material, which ensures starvalves backburn protection.

14. Double centrifugal fans with an air flow of 17.000 m³/h with inverter.

Optional Equipment :

Lambda Sensor

Lambda Sensor  GSM modem

GSM modem

Hot Air Blower

Hot Air Blower

4Heat - Smartphone Application

4Heat - Smartphone Application

H CaminoDesing serves for 40 years the production of heating systems with respect for people and the environment. The PelletTech boilers have been built to serve the needs for industrial heating with quality performance and maximum operating economy.