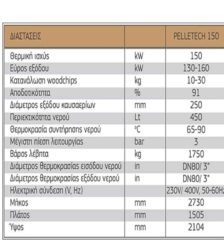

Description

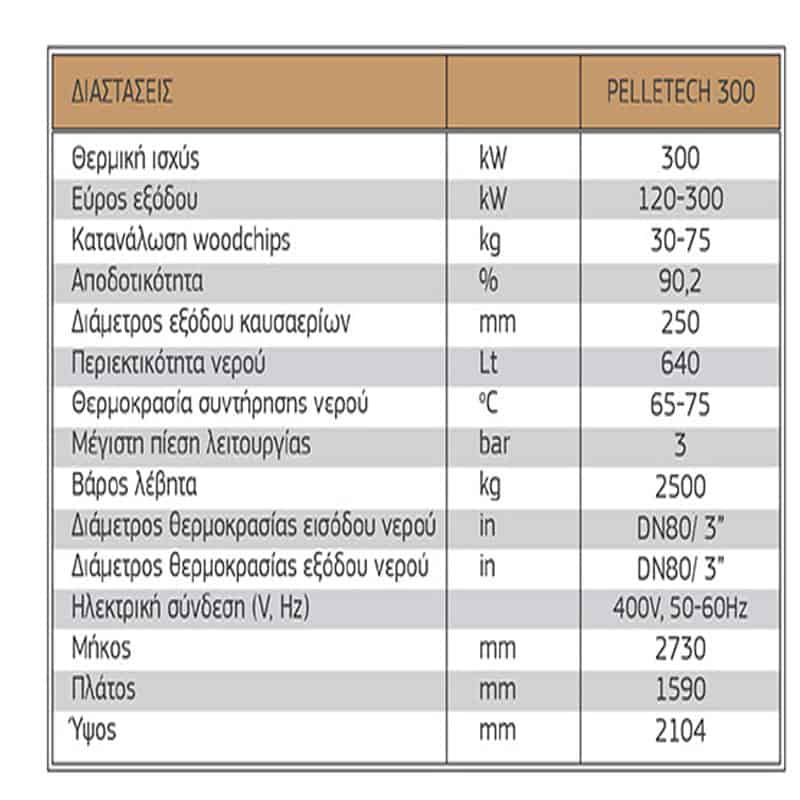

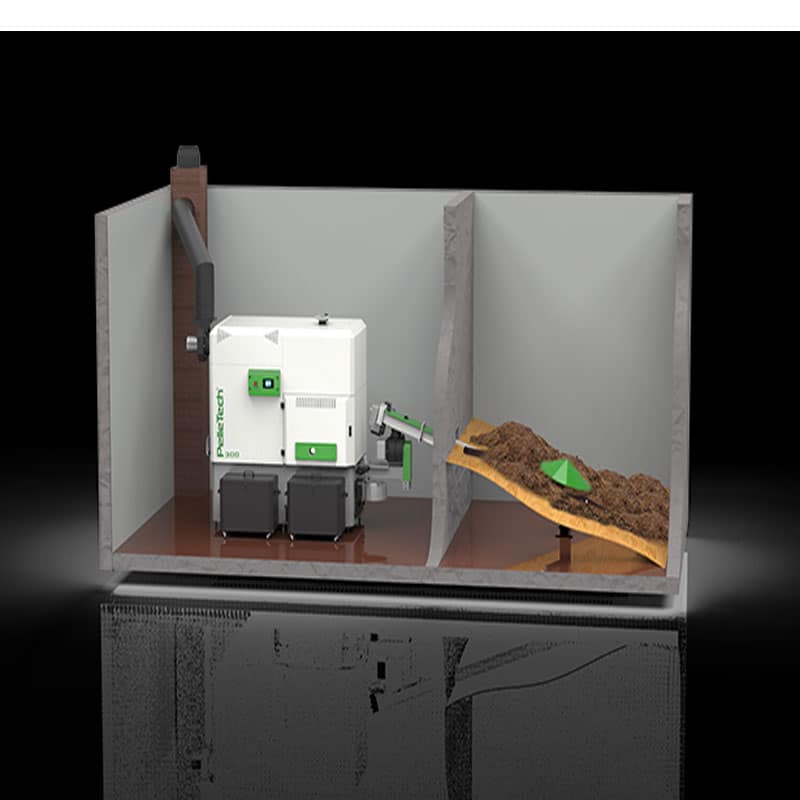

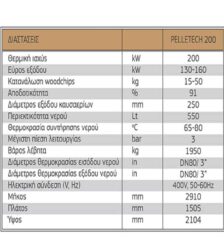

Biomass boiler - Woodchips PelleTeck Idro 300

- Combustibility : Olive kernel , Pellet , Pellet , Crushed olive branches in the form of woodchips and any form of crushed fuel . Maximum moisture content of Biomass Fuel up to 30% .

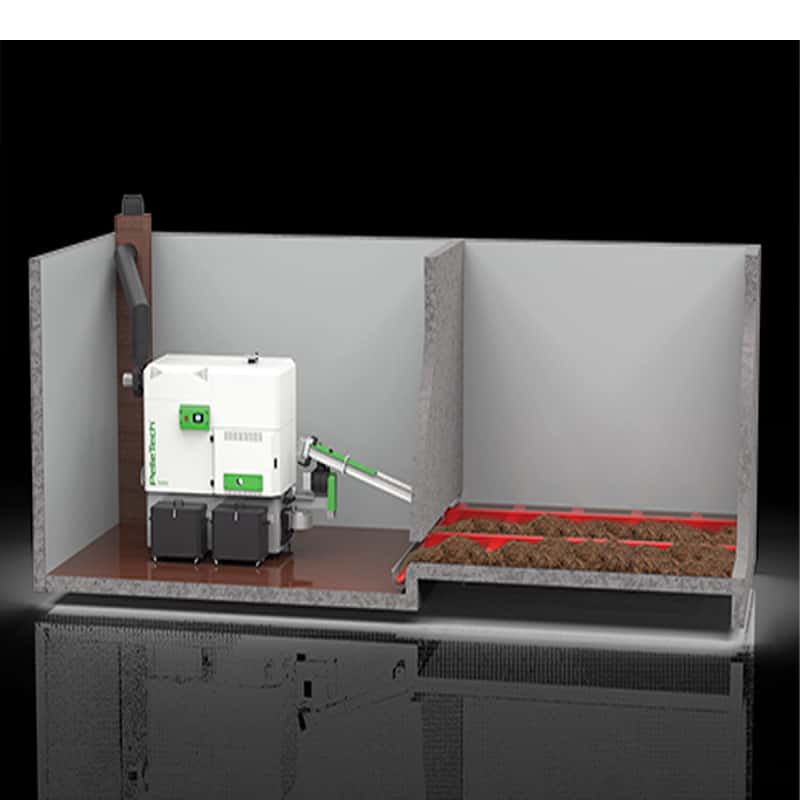

- Integrated System Hot water production

- System Automatic ignition

- System Automatic Cleaning & Extraction ash residues with zero maintenance costs.

- System Configuration management combustion depending on fuel type

- Ability to optimise combustion with Lamda sensor

- Located at independent dual air supply primary and secondary combustion for excellent combustion and proper utilization of bio-fuel without losses.

- Innovative cast iron burner system reciprocating rack with seven (7) steps which allows the combustion of biomass even at increased humidity up to 30%

- Continuous displacement, flotation, full oxygenation and excellent combustion of all types of biomass.

- Construction of combustion chamber from heavy duty steel with reinforced liningmade of refractory concrete, with a long service life.

H CaminoDesing serves for 40 years the production of heating systems with respect for people and the environment. The PelletTech boilers have been built to serve the needs for industrial heating with quality performance and maximum operating economy.

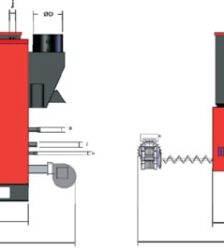

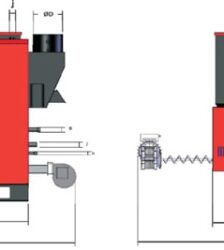

1. 7-stage reciprocating cast iron burner with the ability to burn materials even with moisture content exceeding 60%.

2. Main combustion air supply blower with inverter.

3. Secondary combustion air supply ports that provide additional controlled air supply to the exhaust gases, enrichment and ignition for excellent combustion quality and high efficiency.

4. Reinforced fuel supply bolts of large cross-section with the ability to carry Wood Chips up to type G50.

5. Cast-iron feed system with rotating compartments (SBP) for the supply of combustion material, which ensures starvalves backburn protection.

6. New generation dual fuel engines, high efficiency with very low energy consumption, meeting all new European directives.

7. System for automatic cleaning of ash from the combustion chamber by means of bolts and extraction into a container or a central residue collection system.

8. Combustion chamber lined with thick refractory concrete at the points of contact between the flame and the walls, which ensures very high resistance to the chemical processes and temperatures that develop in the combustion chamber. The use of pyroconcrete contributes to the development of high temperatures in the flame chamber the smooth drying of liquid materials and their complete incineration.

9. 4 dual-path vertical lobe heat exchanger with integrated retarders that ensure maximum exhaust gas retardation time, increasing efficiency with minimum exhaust emissions.

10. Exchanger cleaning system with automatic reciprocating movement of the retarders at regular intervals, ensuring maximum heat transfer to the water.

11. Electronically controlled traction and exhaust motor to the chimney.

12. Lambda sensor for combustion control and optimisation for maximum efficiency and reduced exhaust gases.

13. Hot air blower for rapid ignition of fuel 1660 W.